| Manufacturer | Neoscan |

| True low-contrast 3D resolution | < 5 um |

| Weight | 210 kg |

Sub-micron pixel size at maximum magnification

With possibility of phase contrast retrieval

Low contrast resolution 2 um

15 x better 3D resolution compared to microCT with 5um source spot size

X-ray source up to 110 kV

Covering a wide range of applications like geology, composites, bone, dental, electronics,…

Fits objects up to 100mm diameter and 200mm length

- Specification

- Description

- Instruction

- Video

| General: | |

| Pixel size at maximum magnification | < 2,5 µm |

| True low-contrast 3D resolution | ≤5 µm |

| Maximum scanning diameter | 100 mm |

| Maximum scanning length | 120 mm |

| Maximum physical object length | 220 mm |

| Radiation safety | < 1µSv/h at 10cm from instrument surface |

| Size / weight | 1050W x 607D x 463H mm / 210kg |

| Power supply | 100 – 240 V AC, 50 – 60 Hz, 3A |

| X-Ray Source: | |

| Type | permanently sealed |

| Emitter | W (Tungsten) |

| Maximum voltage | 100kV |

| Maximum power | 20W |

| Smallest spot size | 5 µm or smaller |

| Automatic filter changer, number of positions | 12 |

| X-Ray Detector: | |

| Image sensor | 7 megapixels active pixel flat panel |

| Camera field of view | 140 x 120 mm |

| Scintillator | GADOX |

| Protection against radiation damages | radiation hardened fiber optics |

| Integrated options: | |

| Micro-positioning stage (travel) | Integrated (10 mm) |

| Power for optional stages through sliprings | 24 W (24 V / 1 A) |

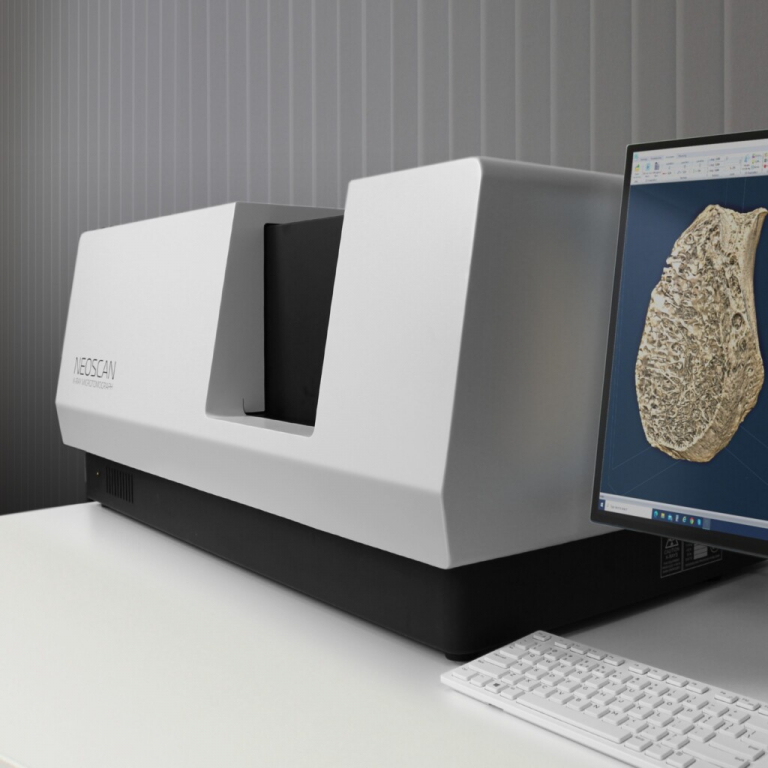

The NEOSCAN N70 is based on newly developed key components, such as a microfocus permanently sealed X-ray source and a large-format flat panel detector, with specially designed precision electromechanical manipulator, new electronics with micro-stepping drives, and integrated software package for scanning, reconstruction, visualization and processing of obtained results.

The X-ray source has a permanently sealed, maintenance-free construction with a smaller than 5 micrometer spot size, which provides very high spatial resolution of the system. Integrated beam repositioning system ensures a long lifetime of the source. 20W source power leads to reduction of the scanning time and an improvement in signal-to-noise ratio.

The X-ray detector contains an active pixel CMOS flat panel bonded to a radiation hardened fiber-optic plate with high-resolution scintillator attached. The large field of view allows scanning big samples and collecting more X-ray radiation emitted by the X-ray source with corresponding reduction of scanning time and improvement of image quality.

The new electromechanical object manipulator in combination with drive electronics for micro-stepping control of all motors provide micron-level accuracy in object positioning and rotation during scanning. The system includes an integrated micro-positioning stage with 10mm travel on top of the object rotation assembly for exact sample positioning or for selection of the scanning volume of interest inside big samples.

The NEOSCAN N70 system includes internal shielding against radiation leaks sufficient for using this instrument in a standard laboratory environment. The shielding is according to all safety regulations without any additional requirements to installation areas. Due to the significant weight, the system should be installed on a strong, stable desk (not supplied with the system) in a vibration-free room.

The system is supplied with a variety of stages for different object sizes including a special stage for large objects with three independently adjustable jaws.

The system can be supplied with an optional workstation in one of two standard configurations with all preinstalled software, or with the software package and all necessary calibration parameters supplied on a USB flash drive for installation on the customer computer. The system requires one USB3 and one USB2 connection to the control computer.

NeoScan software

The supplied software includes an integrated package for Scanning / Reconstruction / Visualization / Processing with friendly Microsoft-Office style user interface. One of four possible modes can be selected through the top tabs from the ribbon-interface.

Optional Parts:

- The NEOSCAN N70 can be supplied with an optional Workstation with all preinstalled software in one of the two following configurations:

“Standard” version: DELL Precision 7820 or similar:

- Intel XEON Silver, 8-cores, or better processor,

- NVIDIA 8GB graphics card,

- 96GB RAM,

- 512GB Solid State Drive for OS and programs,

- 8TB, 7200rpm SATA HDD,

- QWERTY keyboard, optical mouse,

- 24-inch UltraSharp LCD monitor, 1920x1200 native resolution,

- Windows 10 Pro.

“Advanced” version: DELL Precision 7920 or similar:

- Two Intel XEON Gold, 8 cores each, or better processors,

- NVIDIA 16GB graphics card,

- 128GB RAM,

- 1TB Solid State Drive for OS and programs,

- 16TB (2x8TB), 7200rpm SATA HDD,

- QWERTY keyboard, optical mouse,

- 34-inch Ultra-Wide Curved LCD monitor, 3440x1440 native resolution,

- Windows 10 Pro.

Optional Accessories – Thermal stage

The thermal stage allows to perform micro-CT measurements in a temperature controlled environment. The temperature can be changed in-situ allowing to study the effects of temperature on the 3D microstructure of an object.

The thermal stage allows cooling and heating from -40°C below ambient temperature up to +120°C. The object temperature is measured with <1°C accuracy by means of a 48MHz internal microprocessor. The scanner provides power and control signals through a connector on the sample stage, able to supply 24W.

Optional Accessories – Compression/tensile stage

A Compression/Tensile stage allows to perform mechanical tests in situ. This stage allows to study the effect of compression and tension on the 3D microstructure of an object. Compression or tension can be applied in one single device. The accuracy is a fraction of the maximum power, approximately 1%. The maximum load is 1000N. Other load cells with higher accuracy and lower load limits can be supplied on demand.

The maximum dimensions of samples which can be investigated in-situ is mainly determined by the intrinsic material density and mechanical strength, with an upper limit defined by the mechanical design of the compression/tensile stage. The chamber diameter is 30mm.

Optional Accessories – Automatic Sample Changer

The automatic sample changer with 24 sample positions allows scanning series of samples automatically. It is positioned outside of the shielded area so the scanned samples can be removed and new samples can be loaded without interrupting the scanning cycle.

Number of samples: 24 samples

max sample diameter: 30mm

max sample length : 60mm (25mm at high resolution)

Service and Support:

The NEOSCAN N70 system is supplied with standard 12 months warranty. Extended warranty can be purchased separately.

For service and training purposes, it is strongly recommended to get a good internet connection in the computer used for system control.