| Manufacturer | Neoscan |

| True low-contrast 3D resolution | 5 um |

| Weight | 530 kg |

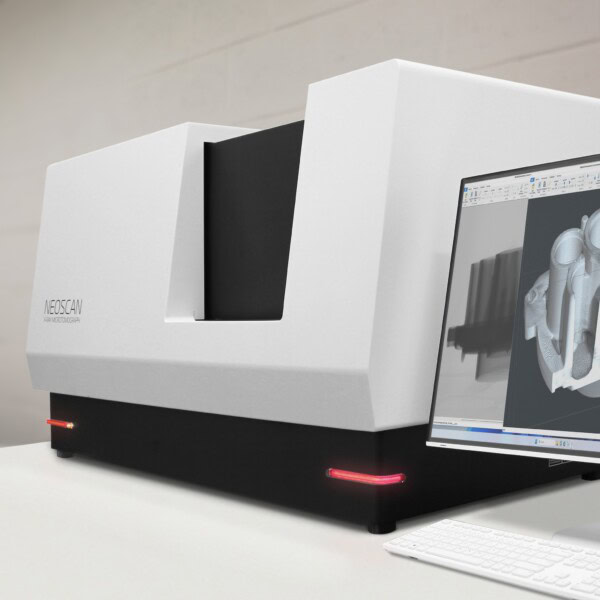

Neoscan NXL desktop micro-CT scanner

NEOSCAN NXL is a powerful benchtop micro-CT system designed for high-penetration imaging. Equipped with a 150kV/75W microfocus X-ray source and a large flat-panel detector, it can scan objects several hundred millimeters in size and materials with high X-ray absorption. The system provides micron-scale spatial resolution, making it ideal for a wide range of applications, from biological specimens (mouse bones, tissue samples, implants, full skulls) to engineering and industrial materials (metals, ceramics, composites, electronics). It is also well-suited for geological samples (drilled cores, rock plugs) and pharmaceutical packaging, delivering detailed, non-destructive 3D reconstructions of internal structures.

- Specification

- Description

- Instruction

- Video

| GENERAL: | |

| Pixel size at maximum magnification | 2.5 µm |

| True low-contrast 3D resolution | 5 µm (at 4W) |

| Maximum scanning diameter | 290 mm |

| Maximum scanning length | 260 mm |

| Maximum physical object diameter | 320 mm |

| Maximum physical object length | 540 mm |

| Radiation safety | < 1µSv/h at 10cm from instrument surface |

| Size / weight | 1500W x 790D x 762H mm / 530kg |

| Power supply | 100 – 240 V AC, 50 – 60 Hz, 4A |

| X-RAY SOURCE: | |

| Type | permanently sealed |

| Emitter | W, reflective target |

| Maximum voltage | 150kV |

| Maximum power | 75W |

| Smallest spot size | 5 µm |

| Automatic filter changer, number of positions | 12 |

| X-RAY DETECTOR: | |

| Image sensor | 13.5 Mp Flat Panel |

| Scintillator | GADOX |

| Protection against radiation damages | Radiation-hardened fiber-optic on sensor, |

| radiation shield over electronics | |

| INTEGRATED OPTIONS: | |

| Micro-positioning stage (travel) | integrated (10 mm) |

| Power for optional stages through sliprings | 24 V / 1 A |

| Shielded passthrough for additional cables/tubes | Integrated |

System Description

The NEOSCAN NXL is based on newly developed key components, such as a microfocus permanently sealed X-ray source and a large-format X-ray detector, with specially designed precision electromechanical manipulator, new electronics with micro-stepping drives, and integrated software package for scanning, reconstruction, visualization and analysis of the obtained results.

The X-ray source has a permanently sealed, maintenance-free construction with a 5 micrometer spot size and 150kV transmission capabilities, allowing a wide range of materials to be scanned. It’s high power results in reduction of the scanning time and an improvement in signal-to-noise ratio.

The X-ray detector contains a super-large format imaging sensor bonded to a fiber-optic plate attached to a high-resolution scintillator. The large field of view allows scanning big samples and the large number of pixels allows achieving a very high voxel resolution for large objects.

These elements combine to a powerful system designed for high-penetration imaging whilst also providing a spatial resolution of 5um in 3D, demonstrated in a JIMA/QRM phantom.

The new electromechanical object manipulator in combination with drive electronics for micro-stepping control of all motors provide micron-level accuracy in the object positioning and rotation during scanning. The system includes an integrated micro-positioning stage with 10mm travel on the top of object rotation assembly for exact sample positioning or for selection of the scanning volume of interest inside big samples.

The NEOSCAN NXL system includes internal shielding against radiation leaks sufficient for using this instrument in standard laboratory environment according to all safety regulations without any additional requirements to installation areas. A shielded passthrough allows additional cables/tubes into the sample chamber. Due to the significant weight, the system should be installed on a strong, stable desk (not supplied with the system) in a vibration-free room.

The system is supplied with a variety of stages for different object sizes, and contains an integrated stage for large objects with three independently adjustable jaws.

The system can be supplied with an optional workstation with all preinstalled software, or with the software package and all necessary calibration parameters supplied on a USB flash drive for installation on the customer computer. The system requires one USB2 connection and one 2.5 Gbps or faster connection (RJ45) to control computer.

The minimum computer configuration is the following:

- Intel XEON Bronze or Intel Core i7 processor, 2GHz or faster,

- 64GB memory,

- 1TB hard drive or solid-state drive,

- 16GB or better NVIDIA graphics card,

- One available USB2/USB3 port and one 2.5 Gb RJ45 port,

- QWERTY keyboard, mouse,

- 21 inch or larger HD monitor,

- Windows 10/11 Pro.

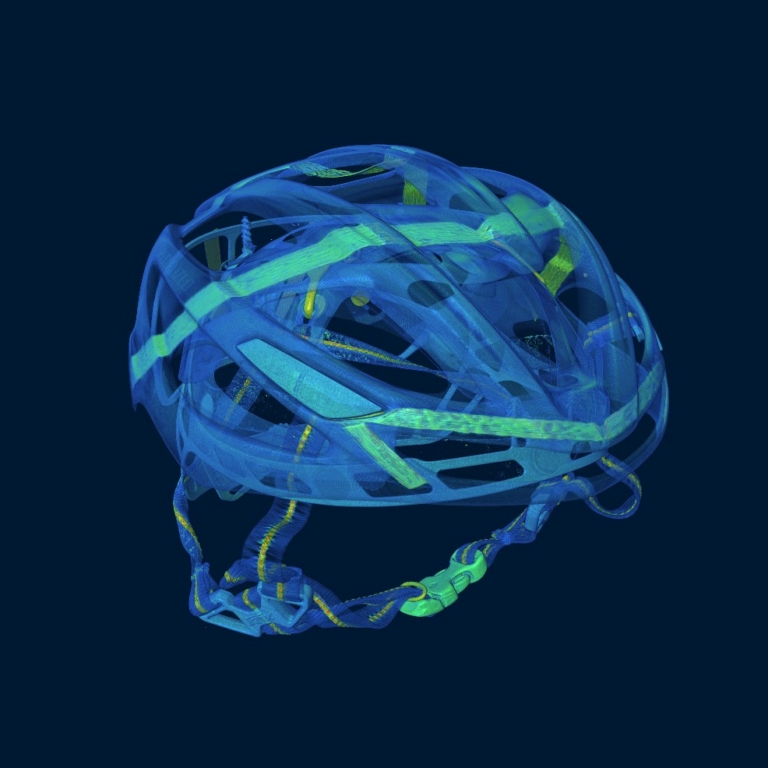

[video width="1280" height="720" mp4="https://klarberg.pro/wp-content/uploads/2025/07/nxl_bicyclehelmet.mp4"][/video]

NEOSCAN NXL

MicroCT scan of a cycling helmet